External processing

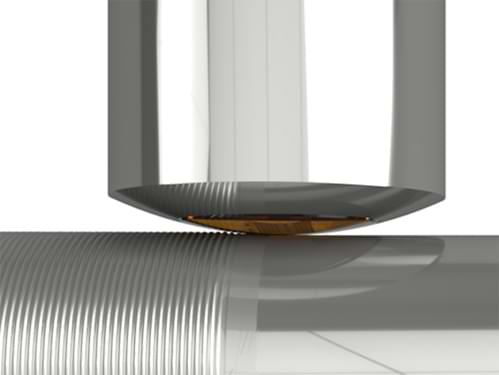

External Diamond Burnishing Tool are designed to produce high-quality, low micron burnished finishes on cylidrical parts, conical parts, shafts, piston rods, rolls and faces. They are suitable for both large and small diameters, making them ideal for wide range of applications even hard machining and thin walled workpieces. Come in multiple designs that can be used on most turning machines whether manual, CNC or Swiss-type machines. The set-up and operation of Diamond Burnishing Tools are very simple, requiring no special operator skills. Can be used on interrupted surfaces, such as shafts with keyways or flanges with bolt holes. These tools can be used with various types of coolants, emulsion or oil, providing necessary lubrication is importent.

Diamond burnishing tools are an economical and user-friendly option for achieving a mirror-like surface finish. They are designed for linear or conical applications and can be used in lathes and similar machines. These tools feature replaceable diamond tips with variation of radius, making them cost-efficient for producing ultra-smooth surface finishes. They All External Diamond Burnishing Tools include a premium quality replaceable diamond tip. These tools are easily adjustable for optimum burnishing pressure, ensuring consistent and precise results. Overall, Diamond Burnishing Tools are a reliable and efficient solution for achieving superior surface finishes in various machining applications.